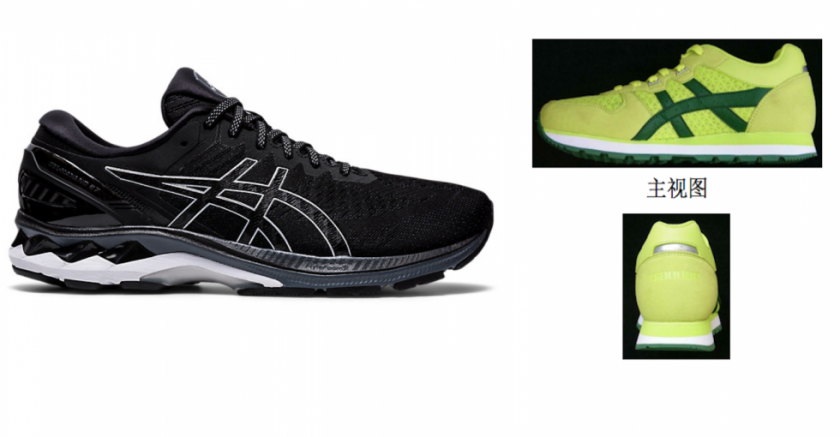

Asics plans to institute a myriad of robots to a plant in Japan that will allow the company more quickly respond to ever-changing consumer trends and ultimately get its shoes on store shelves faster. Next spring up to a third of the production a factory in Tottori Prefecture will be automated. The robots will stitch the upper to the sole and will be used for the Onitsuka Tiger line and for walking shoes.

This automation process will cut in half the number of workers needed.

To keep labor costs under control, Asics produces approximately 40% of footwear in Vietnam, with other factories in China and Indonesia.

The lag time in responding to rapidly changing consumer was an issue for Asics due to the amount of time it takes to ship from the production locations previously mentioned to major markets such as the United States, Japan and Europe. Combine that with the increase in wages that Vietnam and other nations are experiencing due to economic growth and the human rights concerns these nations are facing over excessive hours and child labor, it becomes clear why the decision to at least partially automate was made.

Asics wants to get automation, which currently accounts for less than 10% of its overall production, down pat in its Japanese home market before eventually expanding its robot production in the United States and Europe.